Click to download our Hose Installation Guide

Prior to hose installation:

1. Examine the hose for any obvious damage. IF THE HOSE IS DAMAGED, DO NOT USE. Examples of damage may include slices to the cover, kinks, broken braid, and crushing of the hose (can reduce life and pressure rating).

2. Review application to ensure proper selection of hose has been made by examining materials, pressures, chemical compatibility, temperature and environment.

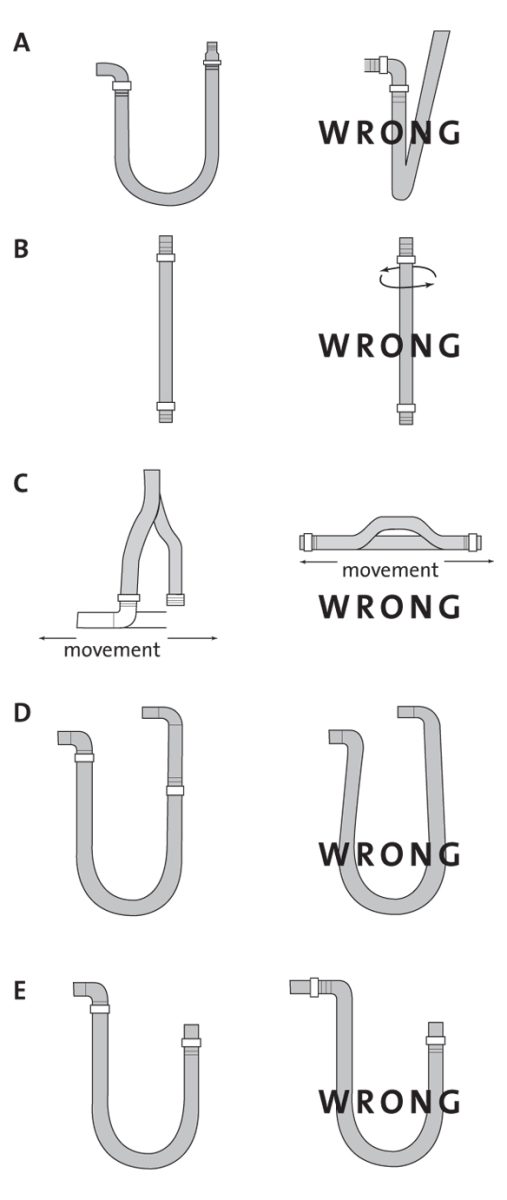

3. Hose movement should be restricted to a SINGLE PLANE (Drawing A) to minimize the resultant twisting (torque).

Note: The flexing plane should also be the plane in which the bending occurs. Excessive bending will induce stress fatigue (Drawing B).

4. Axial movement should be eliminated. The hose should not be stretched or compressed along its longitudinal axis when installed in-line (Drawing C).

Installation:

Never use hose below minimum bend radius (Drawing D). Bend radius (measured to inside radius of fluoropolymer-lined hose and centre line for stainless steel metal hose) are given for individual products and sizes (consult factory for specific data).

These values represent the minimum bend radius with which the hose can be properly installed. If these values are not maintained, the hose can fail prematurely.

Note: In some cases, vacuum and pressure ratings are based on not exceeding 2% minimum bend radius (consult factory for specific hose ratings).

Do not allow severe bends (Drawing E). Severe bends can cause kinking in a hose or overstress the assembly/material, resulting in damage and ultimate failure. If severe bends cannot be avoided, use elbows designed to accommodate the direction change.

Do not twist (torque) assembly along centre line during installation. The likelihood of leakage/failure increases for hoses that are twisted (torqued) during assembly. The proper use of floating flanges and swivel-type fittings (i.e., JIC) can eliminate improper twisting.

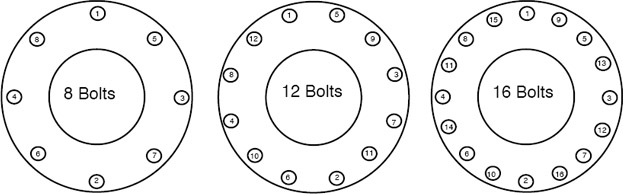

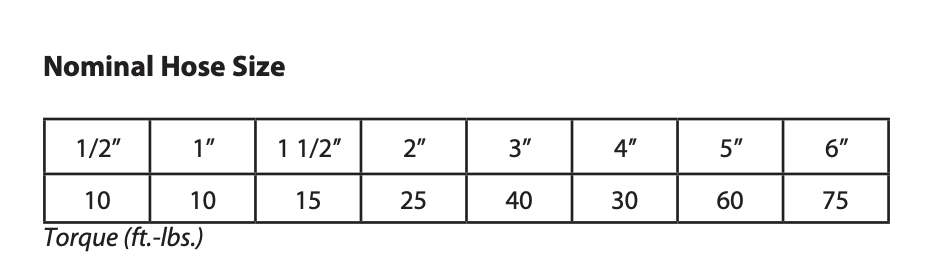

For accurate tightening a torque wrench is HIGHLY recommended. If a flange leak occurs on one side of a properly torqued flange, the bolts should not be over-torqued. Instead loosen the bolts on the non-leaking side the same amount you tighten the bolts on the leaking side.