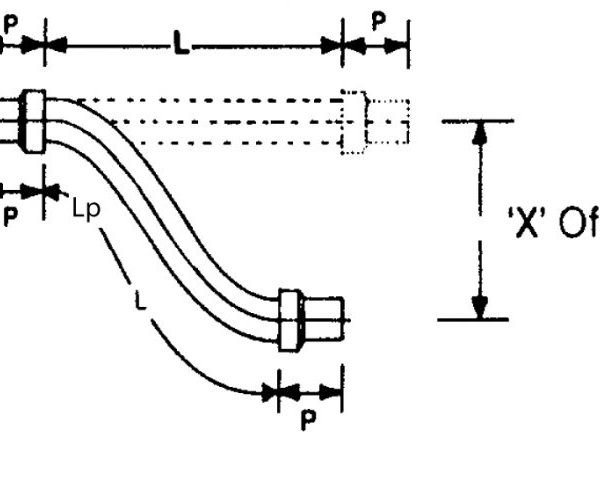

1. Offset Motion

Offset motion occurs when one end of the hose assembly is deflected in a plane perpendicular to the longitudinal axis with the ends remaining parallel.

Formula: L=√6RX+X² Lp=√L²-X²

L = Live hose length (inches).

Lp = Projected Live Hose Length (inches).

R = Minimum Centre Line Bend Radius for constant flexing (inches).

X = Offset Motion to one side of Centre line (inches).

* Formula must only be used in inches

Note 1: when the offset motion occurs to both sides of the hose centre line, use total travel in the formula; i.e. 2 times ‘’X’’

Note 2: The offset distance ‘’X’’ for constant flexing should never exceed 25 percent of the centre line bend radius ‘’X’’

Note 3: If the difference between ‘’L’’ and ‘’Lp” is significant, exercise care at installation to avoid stress on hose and braid at the maximum offset distance.

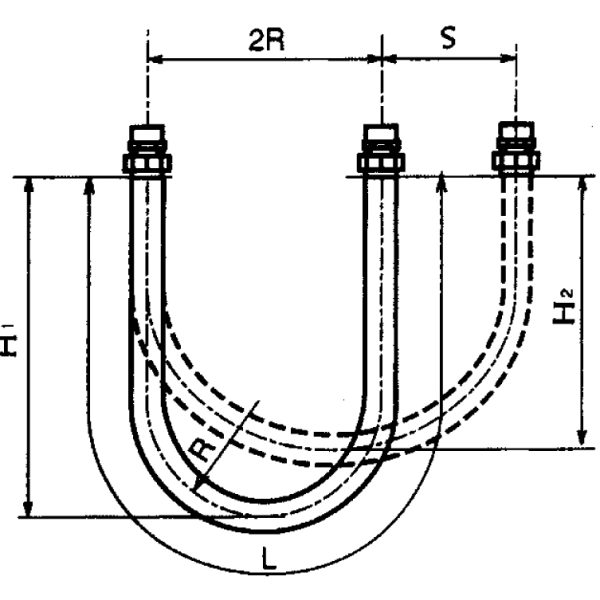

2. Horizontal Movable Pipe System

L= 4R+1.57S.

H1= 1.43R+0.785S.

H2= 1.43R.

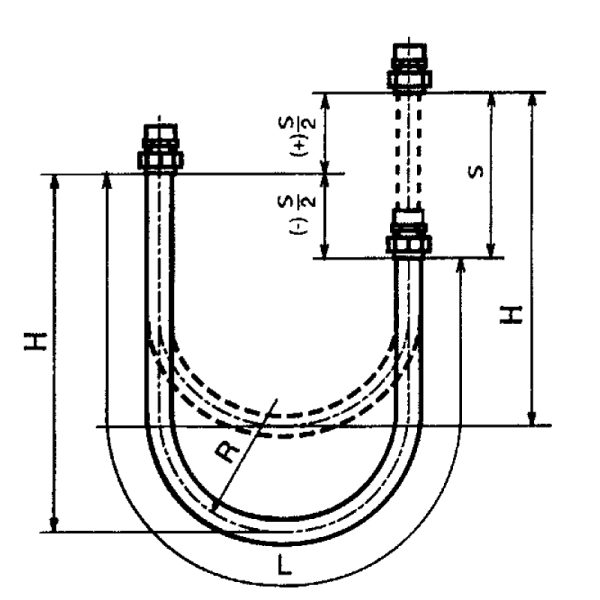

3. Vertical Movable Pipe System

L=4R+.

H=1.43R+.

Illustration of Mark

S: Volume of Variation.

L: Length of Variation.

0: Angle of Variation.

π: Pi 3.142.

R: Min centre line bend radius for constant flex.

Lp: Project live hose length.

Trust us for expert advice and professional service

Contact Us