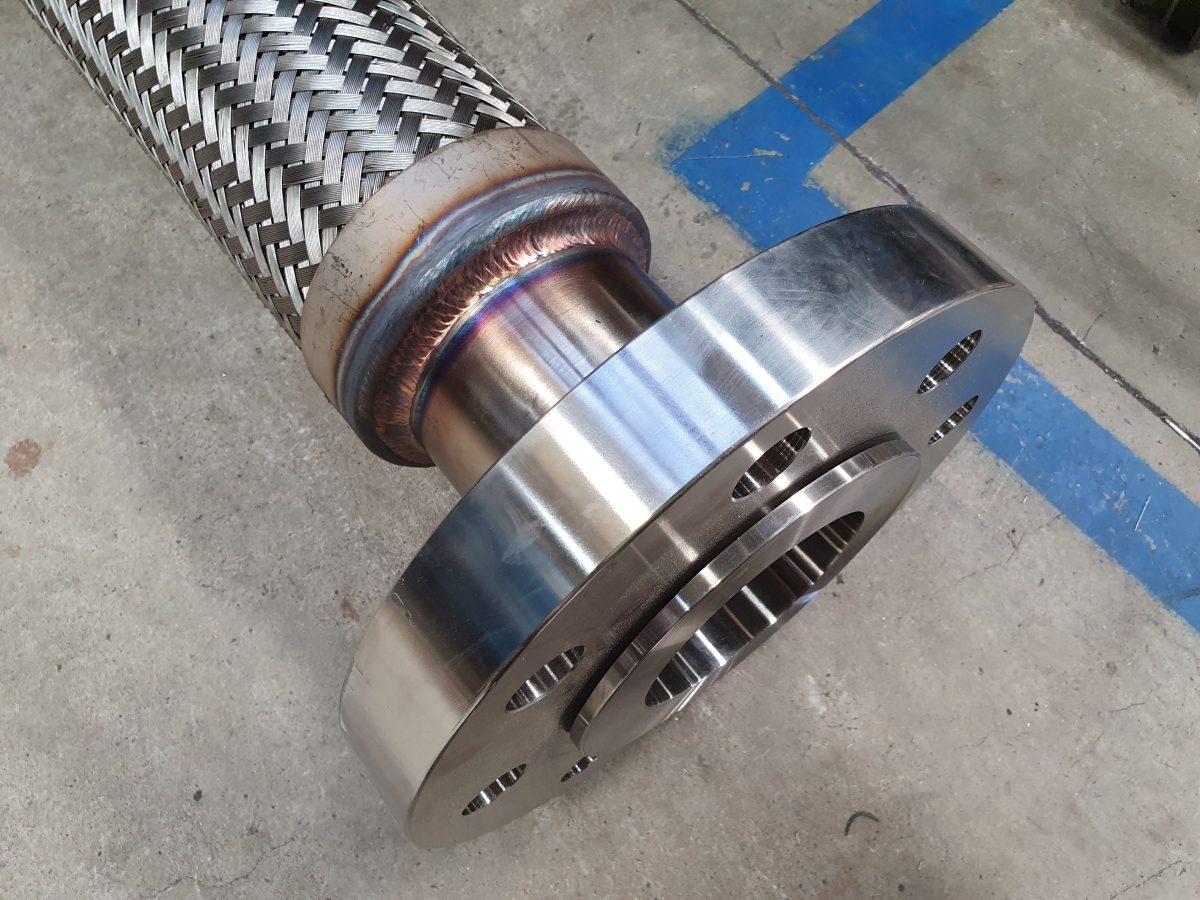

Pacific Hoseflex’s skilled team of qualified welders works with a variety of materials including carbon steel, stainless steel and other high-grade alloys. We provide comprehensive welding services for a range of applications, including:

Our welding services encompass a range of techniques, such as Gas Tungsten Arc Welding (GTAW), Metal Inert Gas Welding (MIGW), Manual Metal Arc Welding (MMAW) and Flux Cored Arc Welding (FCAW).

These welding techniques are used to meet the standards of the following capabilities: Purge Weld | AS 1869 | AS 3992 | AS 4041 Class 1 | AS 4631 | ASME IX | ASME B31.3 | AS/NZS 1554.1

At Pacific Hoseflex, our welding services include a variety of test methods to ensure the highest quality and integrity. We employ pneumatic, nitrogen, helium, hydrostatic, and vacuum tests to assess the strength and reliability of our welds under different conditions.

Additionally, we utilise dye checks and X-ray inspections to detect any surface defects or internal flaws that may compromise the weld’s structural integrity. For a more in-depth analysis, we conduct macro-metallographic examinations to study the microstructure and properties of the weld.

Trust us for expert advice and professional service

Contact UsPacific Hoseflex’s skilled welding team is experienced in working with a variety of materials, including carbon steel, stainless steel, and other high-grade alloys. This versatility allows us to cater to different project requirements and ensure optimal results.

Pacific Hoseflex provides comprehensive welding services for a wide range of industries.

Our expertise covers various applications, including food processing, pressure vessels, gas/oil lines, water treatment, pharmaceuticals, medical equipment, hydraulics, flexible hose assemblies, and pipelines for gas, oil, water, slurry, mining, and coal seam gas.

Pacific Hoseflex employs various welding techniques to meet different project specifications.

Our skilled welders are proficient in Gas Tungsten Arc Welding (GTAW), Metal Inert Gas Welding (MIGW), Manual Metal Arc Welding (MMAW), and Flux Cored Arc Welding (FCAW). This allows us to adapt to specific welding requirements and ensure superior results.

Pacific Hoseflex’s welding services meet rigorous standards and capabilities.

Our welds adhere to standards such as AS 4631-2005, AS/NZS 1869:1996, AS/NZS 3992:1998, ASME IX:2010, ASME B31.3:2008, AS4041:2006 Class 1, and AS/NZS 1554.1:2004 – Structural Steel Welding. Additionally, our capabilities include purge, NATA approval, and compliance with AGA requirements, ensuring the highest quality and safety standards are met.