PTFE Hose Design Introduction

Polytetrafluoroethylene (PTFE) is an engineered fluoropolymer. Outstanding resistance to chemicals is one of its primary attributes.

All PTFE products are either post sintered or slow sintered. Post sintered PTFE gives the best overall performance on permeation therefore is better for use with gases. Slow sintered allow for a better level of permeation but not as good as post sintered. Slow sintered PTFE is mainly used for fluids. Post sintered in available in the UHP-PTFE (Ultra High Pressure Smoothbore PTFE) Range.

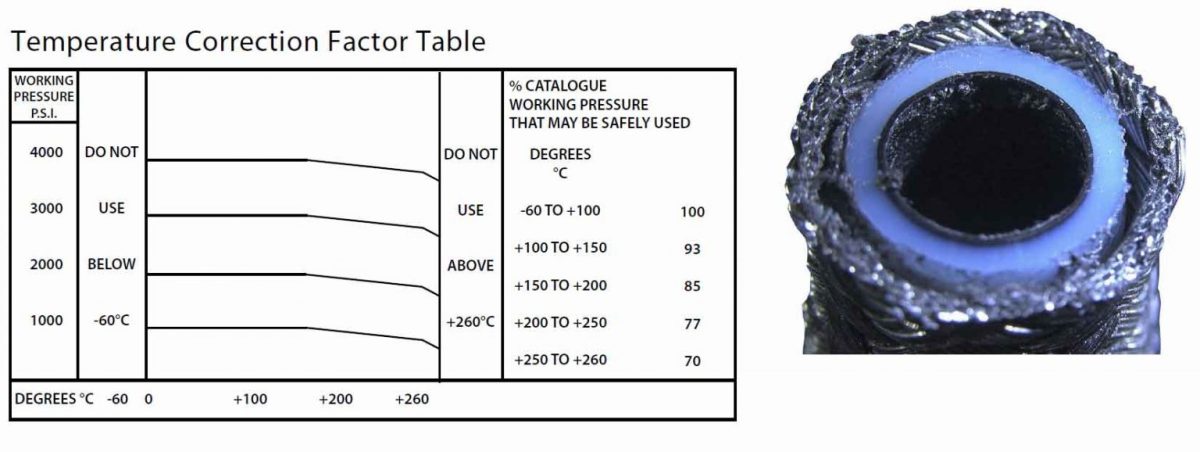

A broad temperature range of -54°C to 260°C makes this hose material suitable for the majority of fluids and ambient temperature conditions found in most industries. With all types of hose, increased working temperatures require a reduction in maximum rated working or burst pressure. Whenever excessive flexing, vibration, thermal fluctuations or rapid pressure impulsing is in evidence, further caution should be exercised in reducing the maximum working pressure.

An extremely low coefficient of friction (0.05 to 0.20) provides a non-stick surface. Water absorption of PTFE is negligible, less than 0.01% by ASTM test, and it is FDA-approved for food and pharmaceutical use.

Additionally, PTFE will withstand flexing and vibration without failure from flex fatigue. PTFE is chemically inert. It will not break down or deteriorate in service, and it has an unlimited shelf life because properties do not change with age or exposure to weather. PTFE hose can be used in aerospace, automotive, chemical and industrial applications.

Pacific Hoseflex offers PTFE hose in a variety of configurations. PTFE hose innercore is offered in smooth bore, convoluted, smooth inner with a convoluted outer, conductive (Carbon black added) anti-static and non-conductive virgin. Type 304 or 316 stainless steel wire braid is the standard reinforcement with other speciality materials available.

Pacific Hoseflex can offer alternative hose covers for chafe resistance and silicone-covered hose for heat and fire resistance. Alternate braid materials include Nomex braided convoluted hose and Kevlar braided high-pressure smoothbore hose.

All stated burst pressures are static and are measured on samples at ambient temperature from which averages are recorded to create relevant specifications. Proof or test pressures are usually twice working pressure. All burst pressures are conservatively rated to provide a high margin of safety. At working pressure this falls within the range +2% to -4% (1/8” & 3/16” +0% to -6%). Pacific Hoseflex 100% tests all assemblies.

A damaging electrostatic charge can build up inside the hose when electrically resistive fluids are being transmitted at very high flow rates (particularly if the PTFE hose assemblies are lengthy). To prevent this, special carbon is mixed with the PTFE to reduce its resistivity. The need for earth conductor braids or wires in the bore of the hose is therefore eliminated.

Regarding PTFE tubing, PTFE Hose and Hose Assemblies: Please be advised that we have found no instance of the use of bovine or other animal derived materials used in the manufacture of our PTFE braided products. The subject products are 100% animal origin free. Therefore, there is no concern with regard to the BSE/TSE issue in the PTFE tube and hose as defined in specification EMEA 410.01 Rev.2.