To obtain a leak-free flange connection, a proper gasket installation is needed, the bolts must be assign on the correct bolt tension, and the total bolt strength must be evenly divided over the whole flange face.

With Torque Tightening (the application of preload to a fastener by the turning of the fastener’s nut) the correct bolt tension can be realized.

Correct tightening of a bolt means making the best use of the bolt’s elastic properties. To work well, a bolt must behave just like a spring. In operation, the tightening process exerts an axial pre-load tension on the bolt. This tension load is of course equal and opposite to the compression force applied on the assembled components. It can be referred to as the “tightening load” or “tension load”

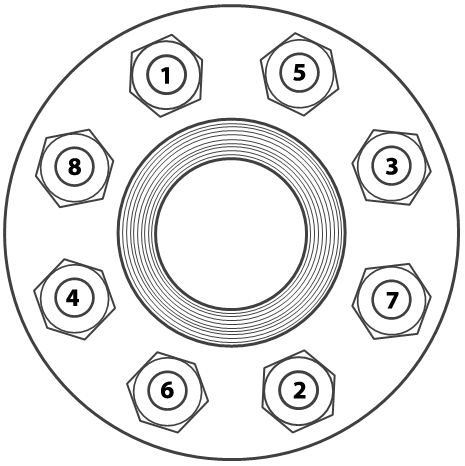

4 and 8 Bolt Flanges

- First round – 30% of final torque (flange sequential order).

- Second round- 60% of final torque (flange sequential order).

- Third round – 100% of final torque (flange sequential order).

- One final time – clockwise or counter clockwise sequentially around the flange.

12 Bolt Torque Pattern For Flanges and More

- First round – 20% of final torque (flange sequential order).

- Second round – 40% of final torque (flange sequential order).

- Third round – 80% of final torque (flange sequential order).

- Fourth round – 100% of final torque (sequential order).

- One final time – clockwise or counter clockwise sequentially around the flange.

The selection of the proper flange bolt tightening technique requires experience. The successful application of any technique also requires qualification of both the tools that will be used and the crew who will do the work.

The following summarises the most commonly used flange bolt tightening techniques:

- Manual Wrench

- Impact Wrench

- Hammer Wrench

- Hydraulic Torque Wrench

- Manual Beam and Gear-Assisted Torque Wrench

- Hydraulic Bolt Tensioner

Bolt Hole Sequence Tightening Sequence

Click to download our Bolt Hole Sequence PDF.