Pacific Hoseflex provides in-house and onsite reliable and accurate testing for various pipework, hoses and connectors. We offer pneumatic, hydrostatic, penetrant, magnetic, radiographic, continuity, third party, holiday/spark, vacuum and cycle testing, oxygen cleaning and positive material identification.

All products are inspected and checked at all manufacturing hold points to comply with a stringent quality management system. All testing equipment is calibrated and certified to comply with ISO 9001:2015.

A full-time level 2 certified testing technician performs all in-house and onsite quality checks and operations. Level 3 and NATA testing can also be completed on request.

Our procedures and practices are conducted in line with our quality program; staff are trained and provided with correct PPE. The in-house activities have been independently evaluated by independent specialists.

NATA accredits organisations to perform testing and inspection activities for their products and services. This gives consumers the assurance they need to make safe, healthy and reliable choices. When you become NATA accredited, you can be sure of a number of competitive advantages for your business. Accreditation to ISO/IEC 17025 plays an important role in supporting the validity and reliability of results from testing and calibration laboratories across many industry sectors. ISO/IEC 17025 facilitates international cooperation by establishing wider acceptance of laboratory test results between countries and organisations. This not only provides global confidence in the work of an organisation but also promotes national and international trade through the acceptance of test and calibration data between countries, without the need for additional testing.

The accreditation increases the opportunities for the WA branch being able to test and validate products to a high laboratory internation specification which is required by majority of the oil and gas companies. We currently outsource these services which will reduce costs and increase new opportunities within the WA industry. This is a great achievement for Pacific Hoseflex increasing our quality assurance level. Our integrated quality assurance is now recognises as the highest in the fluid transfer industry in Australia and New Zealand.

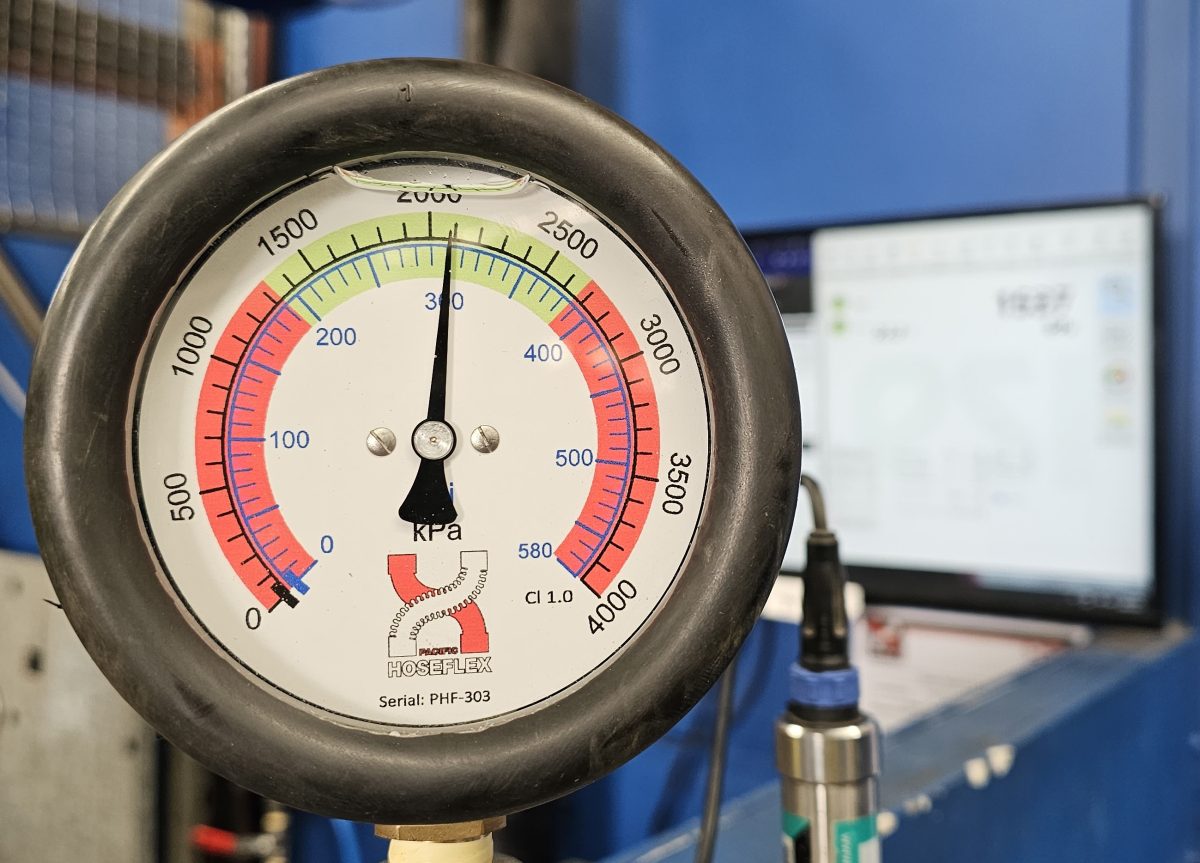

Pacific Hoseflex offers pneumatic testing using a non-flammable gas-like compressed air, Nitrogen, Helium or Hydrogen to identify microscopic cracks and defects in pressure systems. We measure the change in pressure inside systems over a time period.

A pneumatic test is a form of strength test and our experienced and qualified technicians only perform pneumatic tests when:

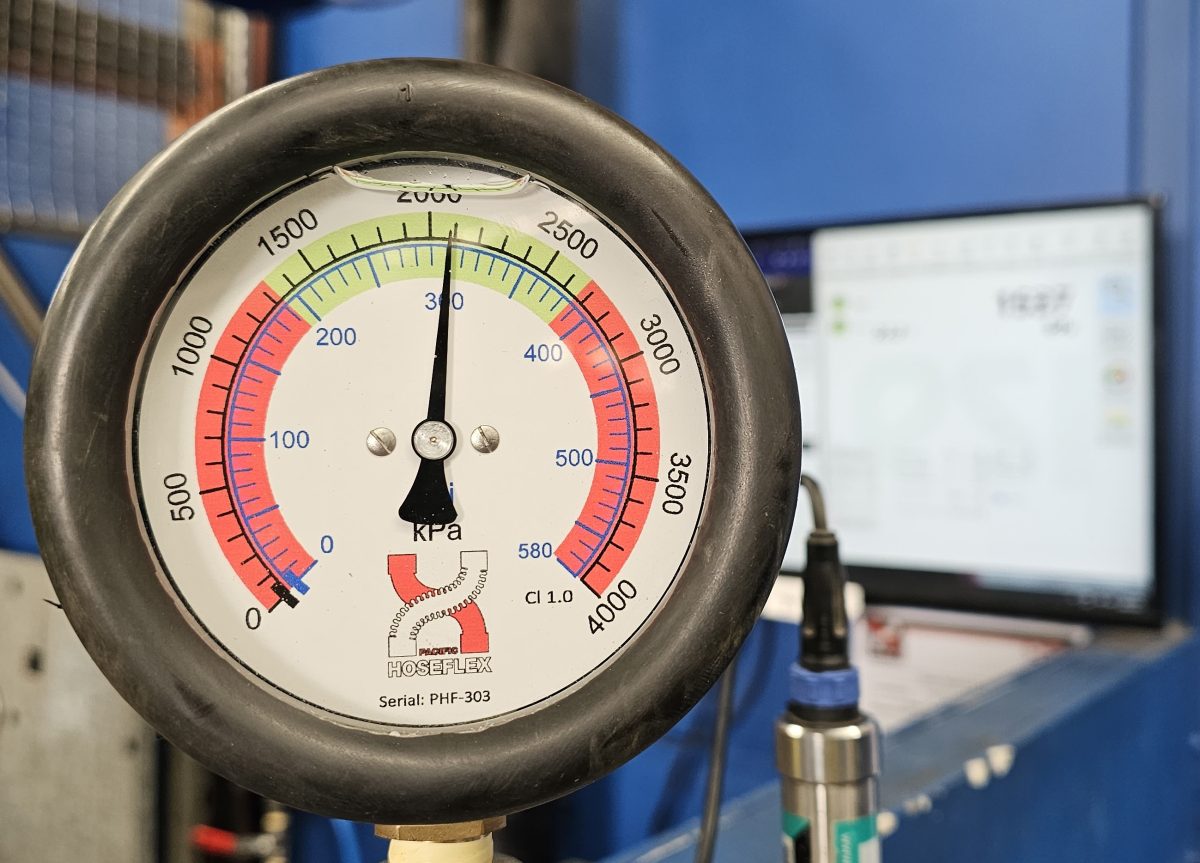

We perform hydrostatic testing by pumping pressurised water into a leak tight system. Once we pressurise the system we can expand it and force water out of any possible cracks, holes or defects. The amount of water that leaves and returns will determine if the system passes or fails the hydrostatic test.

Our hydrostatic testing measures the strength or structural integrity of a pressurised system that holds liquid or gas. We can test boilers, gas cylinders, valves, hoses or water system pipes. As the most common strength testing in piping and hosing systems, we can ensure quality standards with minimum equipment and to Pressure Equipment – Examination and testing AS4037.

NATA Accreditation

ISO/IEC 17025 for pressure testing in accordance with:

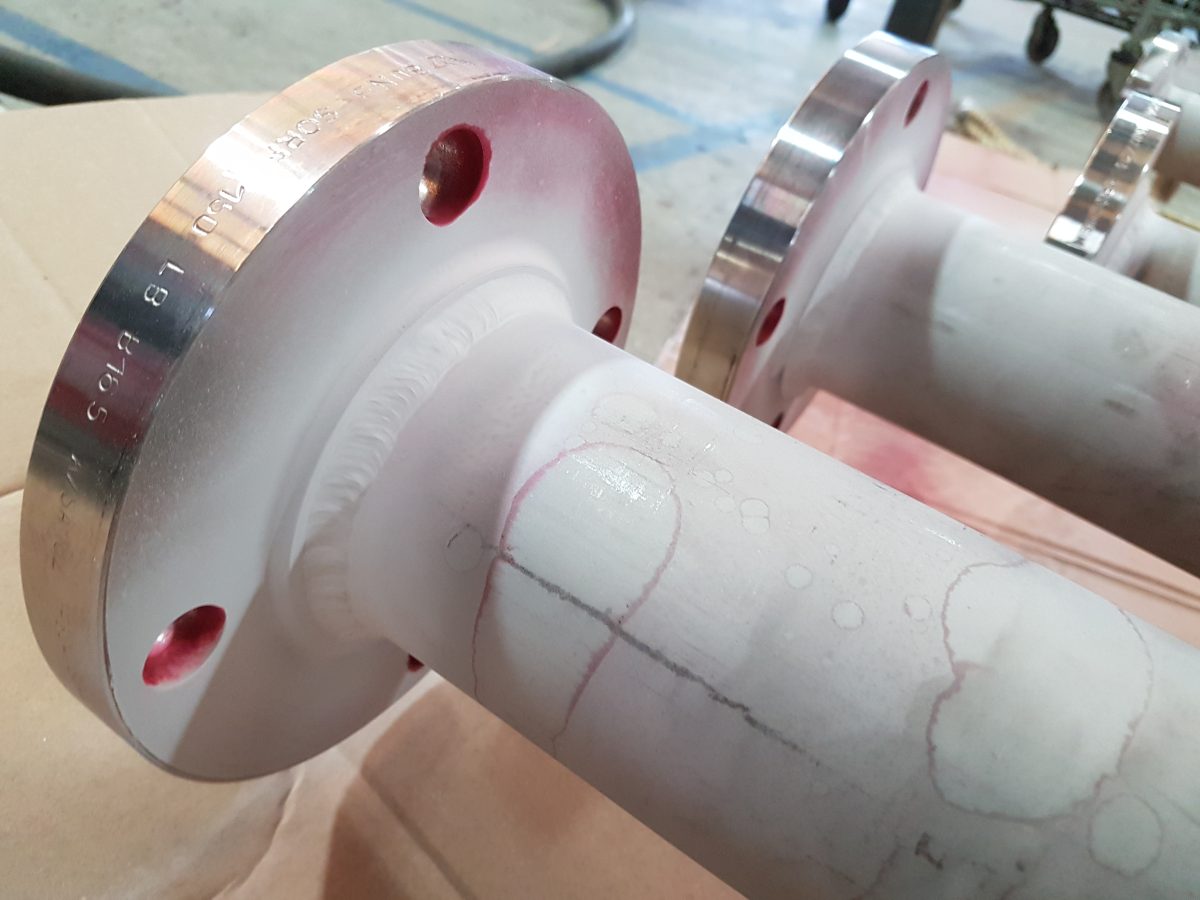

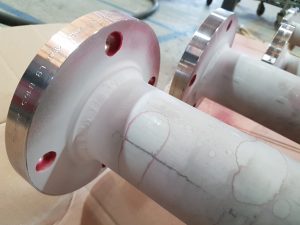

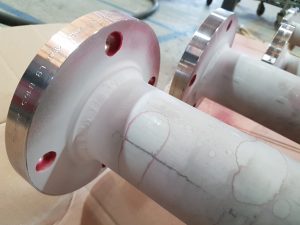

At Pacific Hoseflex, our qualified technicians can efficiently detect hairline cracks, flaws, leaks, surface porosity and fatigue on castings, forgings and welded surfaces through penetrant testing. It’s a low-cost method that requires three solutions; to seep into cracks and flaws, to draw the penetrate out of the surface and then for inspecting the bleeding under natural light.

We perform penetrant inspections on non-ferrous materials in aerospace, shipping and offshore, petrochemical and stainless steel industries to Penetrate Testing of Products and Components – AS2062. We test stainless steel welded joints, aluminium alloy joints, turbine blades, stainless steel fittings, castings and forgings, weld overlays (satellite), aerospace engine parts and more.

Visual Testing (VT) is a fundamental method in non-destructive testing (NDT), focusing on the visual examination of materials, components, or assemblies to detect surface defects and ensure quality.

Applications of Visual Testing

Visual Testing is incredibly versatile, finding use in various industries:

At Hoseflex, we have two technicians fully qualified to ISO 9712:2012 standards, ensuring that our visual testing services meet the highest international benchmarks for competency and reliability. Our skilled inspectors are adept at identifying defects like cracks, corrosion, and misalignments, which helps prevent failures that could lead to costly repairs or dangerous situations. The insights gained from visual testing support material engineers and quality control teams, ensuring that only safe, high-quality products reach the market.

Regular visual inspections are vital for routine maintenance and identifying the root cause of failures. This proactive approach helps extend the lifespan of components and systems, ensuring they continue to operate safely and effectively.

Incorporating visual testing into maintenance and quality assurance programs enhances the reliability and performance of products and infrastructure. It’s a straightforward yet powerful way to detect surface defects and uphold high standards of quality and safety across various industries.

At Pacific Hoseflex, we perform magnetic particle testing on ferromagnetic materials to MT Magnetic Partial Standard AS4041/ASME B31.3 – Pressure Pipe. Our qualified operators place magnetic flux on the system and when a magnetic field is applied, and a crack or other discontinuity is present, the magnetic flux leaks out of the system.

The magnetic flux (magnetic field) will collect ferromagnetic particles (iron powder) as it leaks, making the size and shape of the discontinuity easily visible.

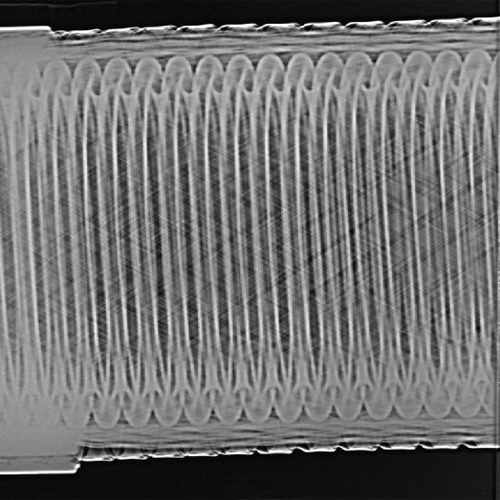

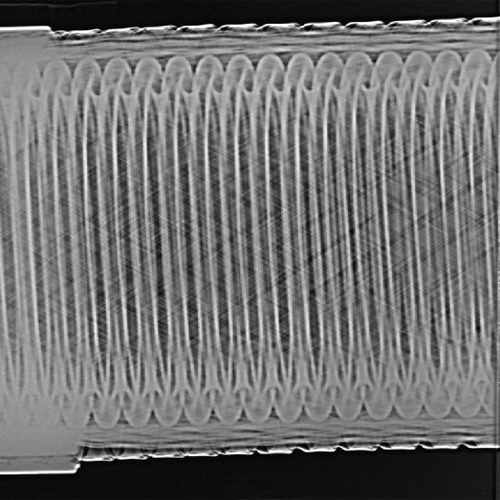

We offer radiographic testing to standard AS4041/ASME B31.3. Through radiographic testing we can establish the weld’s internal integrity without destroying the welded component. Radiographic testing penetrates radiation through a solid object, in this case a weld onto a photographic film, resulting in an image of the object’s internal structure being deposited on the film.

The amount of energy absorbed by the object depends on its thickness and density. Energy not absorbed by the object will cause exposure of the radiographic film. These areas will be dark when the film is developed. Areas of the film exposed to less energy remain lighter. Therefore, areas of the object where the thickness has been changed by discontinuities, such as porosity or cracks, will appear as dark outlines on the film.

Inclusions of low density, such as slag, will appear as dark areas on the film while inclusions of high density, such as tungsten, will appear as light areas. All discontinuities are detected by viewing shape and variation in density of the processed film.

Pacific Hoseflex performs continuity testing which detects the amount of current in a system. This type of testing is completed using multimeters. The calibrated multimeters will determine if the system has an open or closed circuit and the amount of resistance.

We measure the resistance from one end of the system to another in ohms. Depending on the system and relevant standards, limits are set for the maximum or minimum electric resistance.

NATA Accreditation

We offer a range of third party testing including NATA testing, DNV testing, Lloyds testing and NACE testing.

NATA testing: This testing provides independent assurance of technical competence through a proven network of best practice industry experts.

DNV testing: DNV is an international certification body and classification society with it’s expertise in technical assessment, advisory, and risk management.

Lloyds testing: Lloyd’s Register (LR) is a global engineering, technical and business services organisation dedicated to research and education in science and engineering. Lloyd’s have a long-standing reputation for integrity, impartiality and technical excellence. Lloyd’s compliance, risk and technical consultancy services give clients confidence that their assets and businesses are safe, sustainable and dependable.

NACE testing: NACE testing focuses on cathodic protection, coatings for industry, inspection, corrosion testing, and material selection for specific chemical resistance.

At Pacific Hoseflex, we carry out non-destructive Holiday (spark) testing to Holiday/Spark Testing Standard AS3894.1-2002/NACE RP0274-9. We apply a coating to a metallic substrate to prevent corrosion, reduce abrasion and reduce product contamination.

We can identify pinholes, holidays, bare spots or thin points in protective coatings applied for corrosion protection over metal (conductive) surfaces. Holiday testing is suitable for production pipeline coating operations, tank work and structures.

To ensure efficient and dependable performance of hoses designed for vacuum or suction purposes, we offer vacuum testing. This testing is crucial when the intended application demands that the hose withstands collapse in suction and vacuum services.

When a hose is exposed to suction and vacuum, it experiences crushing forces due to the higher atmospheric pressure outside the hose compared to the internal pressure. Without proper construction, the hose may collapse and hinder the flow. Therefore, it is essential to construct the hose in a manner that enables it to withstand these pressure differentials.

Pacific Hoseflex has the facilities, expertise and experience to conduct accelerated life cycle testing on a variety of fluid transfer products. Cycle testing is performed to evaluate and predict reliability and durability of a product using accelerated stress conditions for each life-cycle phase. A life-cycle test can be performed using a success-run or test-to-failure approach and results can identify design weaknesses or evaluate performance at extreme operating conditions.

Reliability determines the support and maintenance cost over the lifetime of a product for both the manufacturer and the consumer. Life-cycle tests can be performed to quantify reliability metrics that inform important decisions about product design and warranty coverage that directly affect the bottom line.

Pacific Hoseflex can work with engineers to develop custom load profiles and life expectancies for a type of testing. Examples of products tested include flexible plumbing fixtures, hoses and flexible seismic products, mining products they requires misalignment components and oil and gas flexible products.

The process of identifying inadequate material grades is a key focus point of Pacific Hoseflex and our team go above and beyond to ensure all products that leave our factory are of a high standard. XRF stands for X-ray fluorescence. It is a powerful, non-destructive technique for measuring elemental composition from Magnesium (Mg) to Uranium (U), from parts per million to 100%.

Handheld XRF analysers are portable and enable us to get lab-quality results on-the-spot to determine the next course of action. The device is a more advance than older spectrometer devices due to is mobility, quickness, reporting and non destructive part analysis. The devices are programmed to mainly identify stainless steel material grades but can give reading on all metallic materials.

Pacific Hoseflex offers pneumatic testing using a non-flammable gas-like compressed air, Nitrogen, Helium or Hydrogen to identify microscopic cracks and defects in pressure systems. We measure the change in pressure inside systems over a time period.

A pneumatic test is a form of strength test and our experienced and qualified technicians only perform pneumatic tests when:

We perform hydrostatic testing by pumping pressurised water into a leak tight system. Once we pressurise the system we can expand it and force water out of any possible cracks, holes or defects. The amount of water that leaves and returns will determine if the system passes or fails the hydrostatic test.

Our hydrostatic testing measures the strength or structural integrity of a pressurised system that holds liquid or gas. We can test boilers, gas cylinders, valves, hoses or water system pipes. As the most common strength testing in piping and hosing systems, we can ensure quality standards with minimum equipment and to Pressure Equipment – Examination and testing AS4037.

NATA Accreditation

ISO/IEC 17025 for pressure testing in accordance with:

At Pacific Hoseflex, our qualified technicians can efficiently detect hairline cracks, flaws, leaks, surface porosity and fatigue on castings, forgings and welded surfaces through penetrant testing. It’s a low-cost method that requires three solutions; to seep into cracks and flaws, to draw the penetrate out of the surface and then for inspecting the bleeding under natural light.

We perform penetrant inspections on non-ferrous materials in aerospace, shipping and offshore, petrochemical and stainless steel industries to Penetrate Testing of Products and Components – AS2062. We test stainless steel welded joints, aluminium alloy joints, turbine blades, stainless steel fittings, castings and forgings, weld overlays (satellite), aerospace engine parts and more.

Visual Testing (VT) is a fundamental method in non-destructive testing (NDT), focusing on the visual examination of materials, components, or assemblies to detect surface defects and ensure quality.

Applications of Visual Testing

Visual Testing is incredibly versatile, finding use in various industries:

At Hoseflex, we have two technicians fully qualified to ISO 9712:2012 standards, ensuring that our visual testing services meet the highest international benchmarks for competency and reliability. Our skilled inspectors are adept at identifying defects like cracks, corrosion, and misalignments, which helps prevent failures that could lead to costly repairs or dangerous situations. The insights gained from visual testing support material engineers and quality control teams, ensuring that only safe, high-quality products reach the market.

Regular visual inspections are vital for routine maintenance and identifying the root cause of failures. This proactive approach helps extend the lifespan of components and systems, ensuring they continue to operate safely and effectively.

Incorporating visual testing into maintenance and quality assurance programs enhances the reliability and performance of products and infrastructure. It’s a straightforward yet powerful way to detect surface defects and uphold high standards of quality and safety across various industries.

At Pacific Hoseflex, we perform magnetic particle testing on ferromagnetic materials to MT Magnetic Partial Standard AS4041/ASME B31.3 – Pressure Pipe. Our qualified operators place magnetic flux on the system and when a magnetic field is applied, and a crack or other discontinuity is present, the magnetic flux leaks out of the system.

The magnetic flux (magnetic field) will collect ferromagnetic particles (iron powder) as it leaks, making the size and shape of the discontinuity easily visible.

We offer radiographic testing to standard AS4041/ASME B31.3. Through radiographic testing we can establish the weld’s internal integrity without destroying the welded component. Radiographic testing penetrates radiation through a solid object, in this case a weld onto a photographic film, resulting in an image of the object’s internal structure being deposited on the film.

The amount of energy absorbed by the object depends on its thickness and density. Energy not absorbed by the object will cause exposure of the radiographic film. These areas will be dark when the film is developed. Areas of the film exposed to less energy remain lighter. Therefore, areas of the object where the thickness has been changed by discontinuities, such as porosity or cracks, will appear as dark outlines on the film.

Inclusions of low density, such as slag, will appear as dark areas on the film while inclusions of high density, such as tungsten, will appear as light areas. All discontinuities are detected by viewing shape and variation in density of the processed film.

Pacific Hoseflex performs continuity testing which detects the amount of current in a system. This type of testing is completed using multimeters. The calibrated multimeters will determine if the system has an open or closed circuit and the amount of resistance.

We measure the resistance from one end of the system to another in ohms. Depending on the system and relevant standards, limits are set for the maximum or minimum electric resistance.

NATA Accreditation

We offer a range of third party testing including NATA testing, DNV testing, Lloyds testing and NACE testing.

NATA testing: This testing provides independent assurance of technical competence through a proven network of best practice industry experts.

DNV testing: DNV is an international certification body and classification society with it’s expertise in technical assessment, advisory, and risk management.

Lloyds testing: Lloyd’s Register (LR) is a global engineering, technical and business services organisation dedicated to research and education in science and engineering. Lloyd’s have a long-standing reputation for integrity, impartiality and technical excellence. Lloyd’s compliance, risk and technical consultancy services give clients confidence that their assets and businesses are safe, sustainable and dependable.

NACE testing: NACE testing focuses on cathodic protection, coatings for industry, inspection, corrosion testing, and material selection for specific chemical resistance.

At Pacific Hoseflex, we carry out non-destructive Holiday (spark) testing to Holiday/Spark Testing Standard AS3894.1-2002/NACE RP0274-9. We apply a coating to a metallic substrate to prevent corrosion, reduce abrasion and reduce product contamination.

We can identify pinholes, holidays, bare spots or thin points in protective coatings applied for corrosion protection over metal (conductive) surfaces. Holiday testing is suitable for production pipeline coating operations, tank work and structures.

To ensure efficient and dependable performance of hoses designed for vacuum or suction purposes, we offer vacuum testing. This testing is crucial when the intended application demands that the hose withstands collapse in suction and vacuum services.

When a hose is exposed to suction and vacuum, it experiences crushing forces due to the higher atmospheric pressure outside the hose compared to the internal pressure. Without proper construction, the hose may collapse and hinder the flow. Therefore, it is essential to construct the hose in a manner that enables it to withstand these pressure differentials.

Pacific Hoseflex has the facilities, expertise and experience to conduct accelerated life cycle testing on a variety of fluid transfer products. Cycle testing is performed to evaluate and predict reliability and durability of a product using accelerated stress conditions for each life-cycle phase. A life-cycle test can be performed using a success-run or test-to-failure approach and results can identify design weaknesses or evaluate performance at extreme operating conditions.

Reliability determines the support and maintenance cost over the lifetime of a product for both the manufacturer and the consumer. Life-cycle tests can be performed to quantify reliability metrics that inform important decisions about product design and warranty coverage that directly affect the bottom line.

Pacific Hoseflex can work with engineers to develop custom load profiles and life expectancies for a type of testing. Examples of products tested include flexible plumbing fixtures, hoses and flexible seismic products, mining products they requires misalignment components and oil and gas flexible products.

The process of identifying inadequate material grades is a key focus point of Pacific Hoseflex and our team go above and beyond to ensure all products that leave our factory are of a high standard. XRF stands for X-ray fluorescence. It is a powerful, non-destructive technique for measuring elemental composition from Magnesium (Mg) to Uranium (U), from parts per million to 100%.

Handheld XRF analysers are portable and enable us to get lab-quality results on-the-spot to determine the next course of action. The device is a more advance than older spectrometer devices due to is mobility, quickness, reporting and non destructive part analysis. The devices are programmed to mainly identify stainless steel material grades but can give reading on all metallic materials.

Trust us for expert advice and professional service

Contact Us