Never underestimate the importance of end-to-end tagging and traceability when maintaining and operating a manufacturing process. Tagging and traceability have many advantages as it enables you to have access to a range of information to ensure transparency and accountability throughout the lifespan of a product.

Traceability assures that you can seamlessly link to the product’s Inspection Test Procedure (ITP), material certification, and quality control measures. By implementing a robust traceability system, Pacific Hoseflex ensures that vital information is readily accessible, allowing you to track the entire history and quality of the product.

Hose tagging for identification

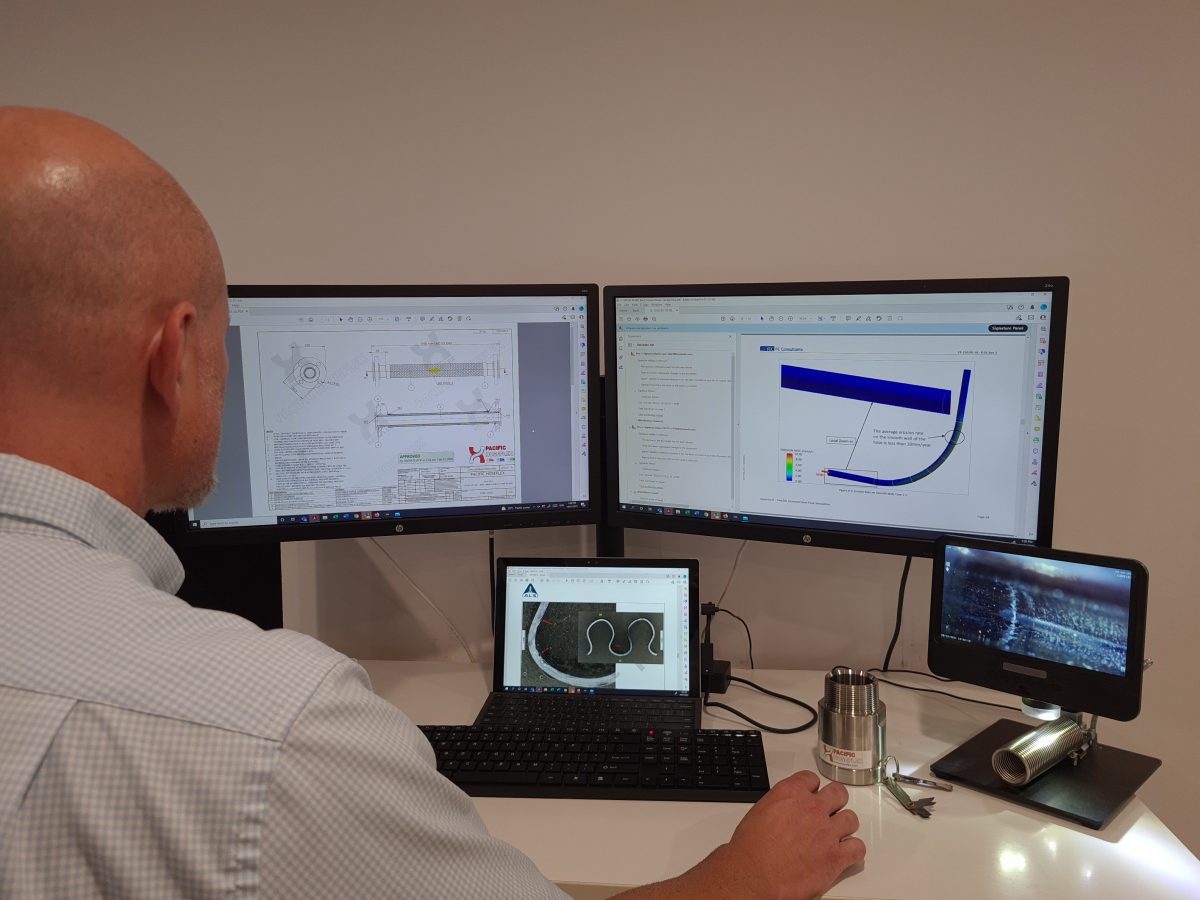

The Pacific Hoseflex team understands the importance of proper identification for management and maintenance. We offer both metallic and non-metallic tags that can be customised to include specific data on all manufactured products and assemblies.

When we engrave each product with a unique number, we can ensure traceability throughout the entire lifecycle of the product. The unique number can be linked back to Pacific Hoseflex’s in-house Inspection Test Procedure (ITP), material certifications, and quality control measures, providing a strong traceability system.

Customised tag data

To enhance traceability and identification, all assemblies purchased from Pacific Hoseflex are tagged, with specific data that is tailored to meet your needs. On our flexible stainless steel hoses, we include vital information such as job numbers, purchase order numbers, descriptions, test pressures, working pressures, dates and approvals (such as AGA and Oxy Cleaned).

By communicating this essential information we can ensure the assembly can be identified, tracked and managed irrespective of where it is in its lifecycle.

Test certificates and record management

To enhance our traceability and tagging systems, Pacific Hoseflex also provides test certificates to our clients. These certificates include the tagged information, along with other relevant information. This ensures complete transparency and documentation of the quality and performance of each assembly.

As an industry leader in fluid transfer products, we also maintain detailed records that improve traceability and records management, giving us easy access to important information whenever it is needed.

What are the benefits of tagging and traceability?

Some of the main benefits of tagging and traceability for the manufacturing end-user include:

- Quality assurance: At Pacific Hoseflex, the tagging and traceability systems we implement conform to the internationally recognised Quality Management System ISO 9001. By engraving unique identification numbers on each product and assembly, we can ensure that quality control measures are upheld throughout the manufacturing process. You can have confidence knowing that our products are compliant.

- Efficient maintenance and management: By using efficient tagging and traceability systems you can streamline maintenance and management procedures. When products and assemblies can be clearly identified it’s easier to schedule inspections, track performance and carry out any relevant maintenance. It helps to reduce downtime and improve operational efficiency.

- Compliance and safety: Tagging and traceability help to ensure you meet regulatory requirements. It’s simple to track and address any problems and take action on any recalls as soon as possible. It also makes it easy to track the materials used in the manufacturing process, contributing to compliance with industry standards and regulations.

- Customer satisfaction: By having an efficient tagging and traceability system we can ensure we only deliver high-quality products and exceptional customer services. We can give you the peace of mind that our products have been through a stringent quality control process and you will have all the information you need to trace them back to the manufacturer.

End-to-end tagging and traceability are essential for any manufacturing and supply chain process. With years of experience in the industry, we understand the importance of implementing comprehensive tagging and traceability measures to ensure the quality, reliability, safety and compliance of our fluid transfer products.

Our system, which includes engraving unique identification numbers, customised tags and test certificates, will help you implement efficient maintenance and management processes. When you partner with Pacific Hoseflex, you can be sure you are working with a hose manufacturer that is committed to delivering exceptional quality products with tagging and traceability systems in place that meet internationally recognised standards.