INDUSTRY SOLUTIONS

No matter what field you're in, we have the perfect solution for you.

ABOUT US

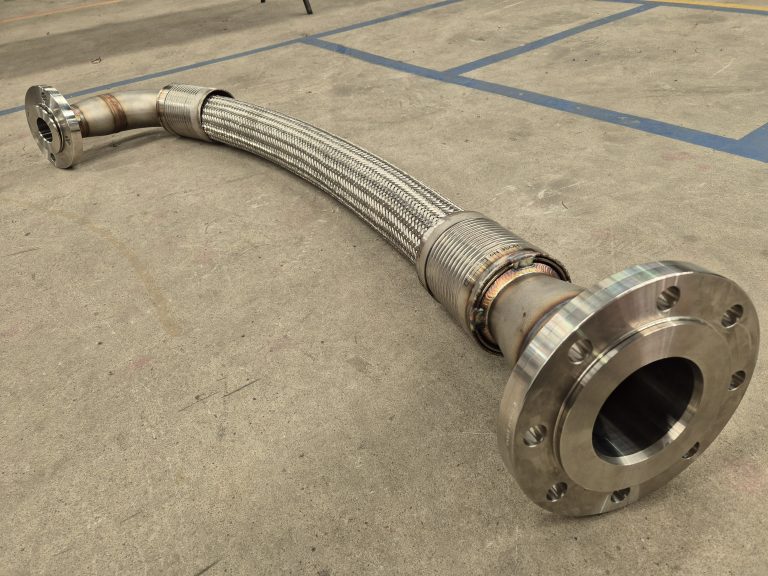

The leader in engineering fluid transfer products

Recognised as the industry leaders in fluid transfer product engineering, we are a third-generation Australian owned and operated business. PHF have the most advanced manufacturing equipment technology in their market, with an electronic scheduling and ERP System and a fully digitalised workplace. This system ensures we keep up-to-date with client needs and the emergence of Industry 4.0 in manufacturing.

Industry Leaders in Fluid Transfer Products

Trust us for expert advice and professional service

Contact Uslatest blogs

VIEW ALL

Ensuring Reliability: The Vital Role of Oxygen Supply Systems

There are many industries where safety and reliability are key, such as medical, biotechnology, aerospace and industrial applications. These systems...

read more

Recognising four generations of engineering at Pacific Hoseflex

This month we celebrate the 30th anniversary of Pacific Hoseflex. As a fourth generation Australian-owned and operated company, we’ve withstood...

read more

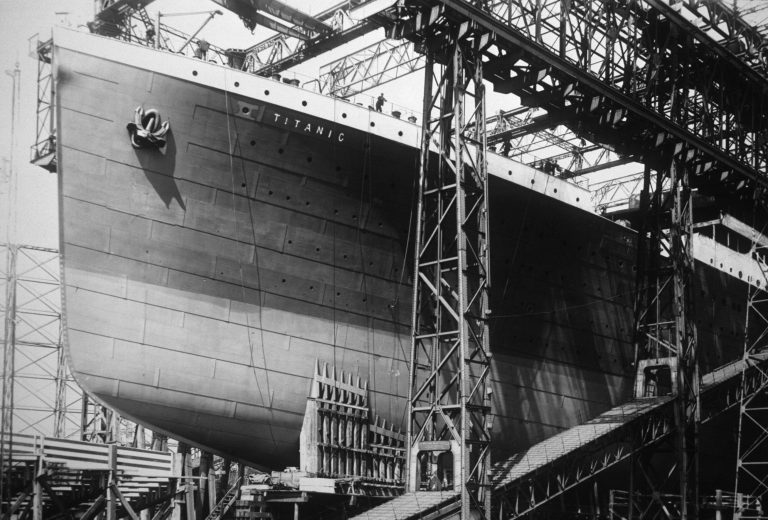

Visit Pacific Hoseflex at the AOG Energy conference

We’re excited to announce that Pacific Hoseflex will have a stand at the upcoming AOG Energy Conference at the Perth...

read more