Regardless of what industry you’re part of, custom-designed hose assemblies provide a valuable solution to optimise fluid transfer operations and ensure efficient and reliable performance. Thankfully, Pacific Hoseflex is well-equipped to meet the increasing demand for custom-designed hose assemblies that cater to specific industry requirements.

By utilising innovative technologies, ensuring a commitment to quality and offering a customer-centric approach, Pacific Hoseflex stands out as a third-generation Australian owned and operated business catering to a diverse range of industries worldwide.

Advanced technology

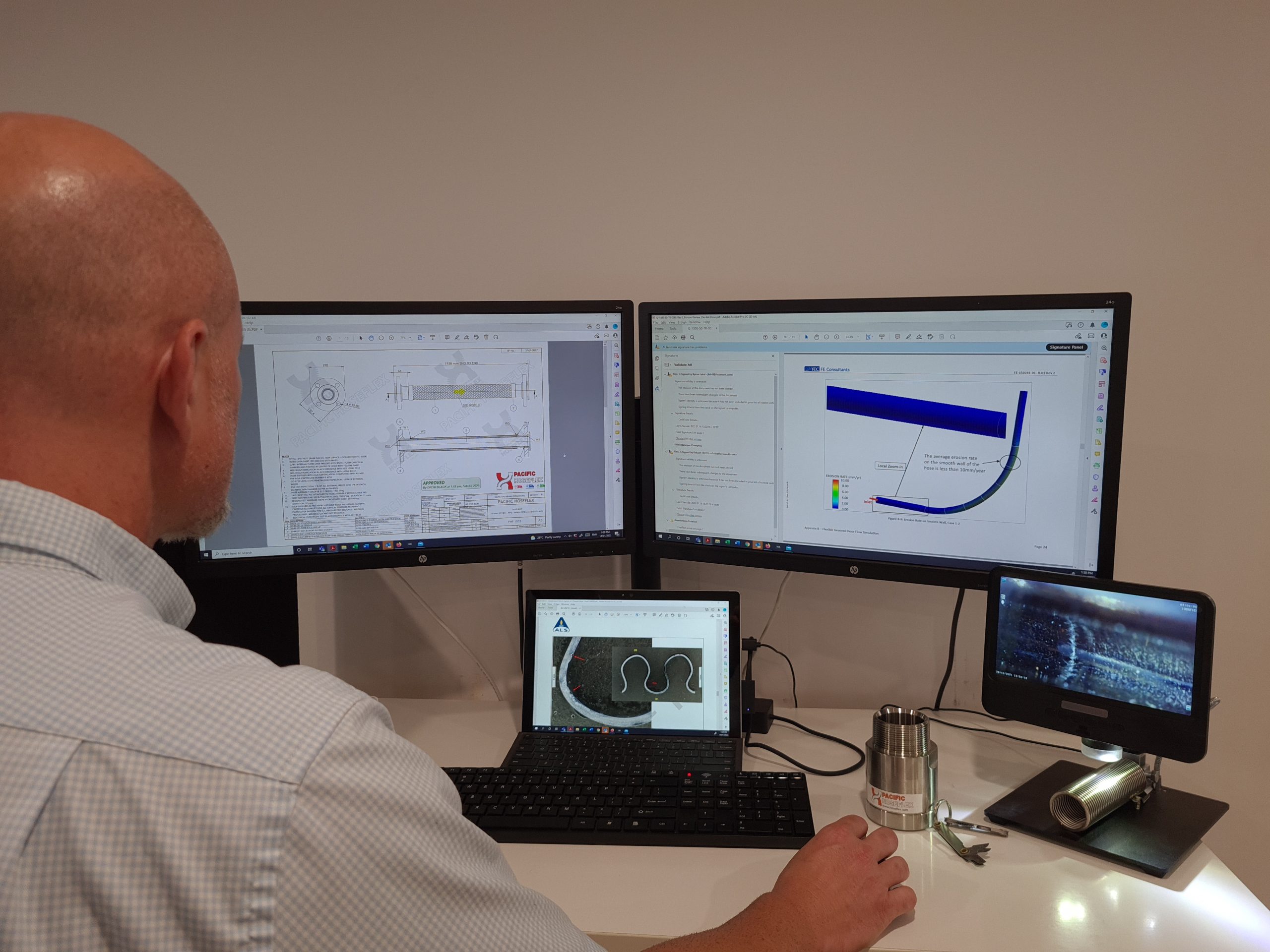

It’s impossible to be a leader in the hose industry without embracing the latest technology in the market. At Pacific Hoseflex, we leverage an electronic scheduling and ERP system along with a digitalised workplace.

A forward-thinking approach that embraces innovative new practices for custom-designed hose assemblies is essential to ensure we keep up with client’s needs. In applying Industry 5.0 we integrate artificial intelligence, automation, big data analytics, the Internet of Things (IoT), machine learning, robotics, smart systems and virtualisation to ensure our manufacturing processes are not only efficient but sustainable.

Engineering excellence for tailored hose solutions

Want to know our competitive advantage? It lies in our extensive research and development and the expertise of our highly-qualified technicians. Our clients receive valuable support and technical information, which includes design and drafting services to ensure each custom hose assembly meets industry and customer standards.

At Pacific Hoseflex we design and manufacture custom hose assemblies according to customer specification, taking a tailored approach to address our client’s unique industry requirements.

By embracing the principles of Industry 5.0, we combine the latest in technological advancements with a focus on sustainability to produce competitive, high-quality products. We use 3D CAD drafting, CNC machining, digitalised crimping, laser tagging traceability, digitalised non-destructive testing reports, and efficient welding techniques to optimise the manufacturing process

- 3D cad drafting.

- CNC machining.

- Digitalised crimping.

- Laser tagging traceability.

- Digitised non-destructive testing reports.

- Efficient welding techniques.

- Live data Integrated digital business management system.

Live data hose management system and traceability

We have a comprehensive hose management system that enables clients to trace and maintain all the products we supply. As every industry is different, we can customise it to suit individual client needs. Our hose management system provides an efficient way to track and maintain hose assemblies throughout their life cycles.

Every custom hose assembly undergoes 100% testing and comprehensive inspection to guarantee the highest quality standards.

Quality assurance

Pacific Hoseflex has a strong commitment to providing superior-quality products. Our certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and ISO 45001 for occupational health and safety management systems.

Pacific Hoseflex adheres to AS/NZS 3992:2015, AS 4041-2006, AS 4631—2005, WMTS 520:2016, and FMV SS106 standards, ensuring compliance with welding and brazing qualifications, pressure and process piping codes, flexibility connectors for gas, and Watermark and DOT approvals.

Furthermore, PHF is a recognised supplier of the Department of Defence and holds approvals from Sabic and the National Iranian Oil Company (NIOC).

The Pacific Hoseflex difference

Experience the Pacific Hoseflex difference with our exceptional team of qualified technicians and our commitment to fast, reliable service. We understand the important role hose assemblies play in various industries and offer assistance in emergency breakdown situations to minimise downtime and loss in productivity.

If you want to work with a business that stands at the forefront of the fluid transfer industry and you are looking for high-quality, custom-designed hose assemblies, contact our product experts today.