As a food and beverage manufacturer, your highest priority is to ensure the quality and safety of your products. Sanitary hoses are essential to food processing operations to ensure products are transferred with maximum safety and efficiency, without contamination.

It’s vital to choose the right sanitary hose for your application. An inferior hose can lead to contamination, manufacturing downtime and significant financial loss. It can even lead to litigation!

Here are a few tips from the Pacific Hoseflex team to help you choose the right food-grade rubber hose for your application:

Size

The hose you choose needs to be a suitable size to avoid any blockages or damage to the product which is being transferred. Using a hose that’s too small, can cause pressure to build up and damage your equipment. Using a hose that’s too big can create inefficiencies in your manufacturing process. Selecting the right size food-grade hoses to maximise efficiency and productivity is vital.

When you purchase a product from Pacific Hoseflex you will have access to expert technical support. Our team has years of experience supplying hoses to the food and beverage manufacturing industry, and will supply a hose that meets your exact specifications.

Temperature and pressure rated

Another important factor is whether the hose is temperature and pressure rated. Hoses need to withstand high temperatures and pressure during the manufacturing process. Cheap hoses may not be durable enough. If they fail or malfunction, it could cause downtime and significant financial loss.

At Pacific Hoseflex, our range of rubber hoses are highly durable and commonly used in food and beverage production. They are available in various materials, sizes and are rated for high temperature and pressure.

Each food-grade rubber hose is pressure and temperature tested to ensure it is suitable for your application.

Material composition

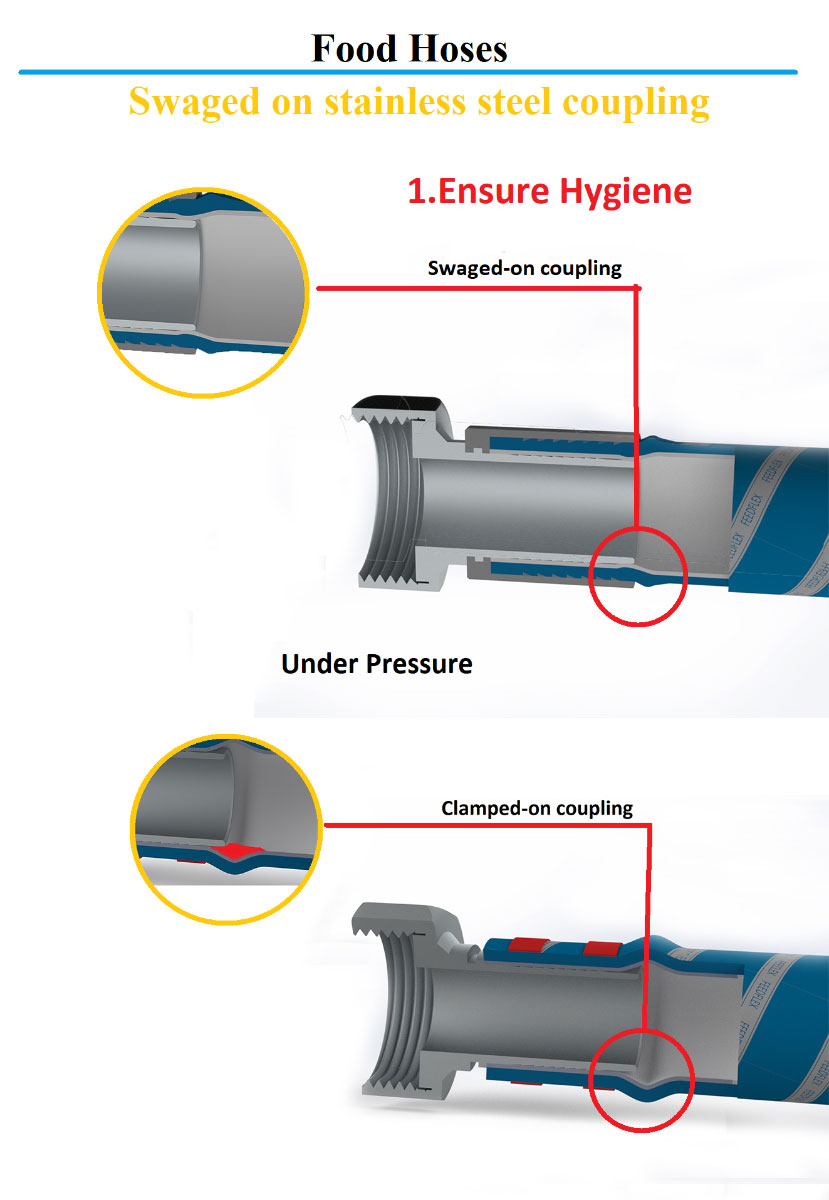

With food and beverage production, it’s essential to consider the material composition of your hoses to ensure they are sanitary. The hose must be constructed from materials that are safe for use in the food and beverage industry.

Food-grade rubber hoses are ideal, as they are non-toxic, won’t affect the taste and are odourless. These factors are vital to ensure your product isn’t contaminated. The material must also be chemical resistant.

Pacific Hoseflex offers a high-quality range of hygienic food-grade hoses and fittings. Our hygienic food-grade rubber hoses prevent contamination and are made for specific applications. From our Edible Oil Hose to our Milk Suction & Delivery FeedFlex Hose and Liquid Delivery Hose, we can tailor a food-grade hose to meet your specific requirements.

Industry compliance

In Australia, we have strict industry standards and regulations. The Australian Government has implemented various regulations and guidelines to ensure food safety and quality. Food and beverage manufacturers must comply with these regulations.

Pacific Hoseflex food-grade hoses comply with FDA standards and abide by all relevant food Australian industry regulations.

Choose the right food-grade hose manufacturer

To choose the right food-grade rubber hose, you must engage a reputable hose manufacturer. Only reputable and reliable manufacturers will provide quality hoses and the customer support and advice you need.

When selecting a hose manufacturer you must consider industry experience and reputation, quality control processes, flexibility to customise products and ongoing customer service.

Your hose manufacturer must have a great understanding of your industry needs and all relevant regulatory requirements. You should be able to rely on them for trusted advice.

They should also have strict quality control measures in place. At Pacific Hoseflex, we test all products and are dedicated to providing superior quality products and services.

We have achieved ISO 9001: Quality Management Systems, ISO 14001: Environmental Management Systems, ISO 45001: Occupational Health and Safety Management Systems. We also have AS 4041-2006: Pressure piping, ASME B31.3 Process Piping Code and all relevant certifications for the food and beverage industry.

After purchasing your food-grade rubber hoses from Pacific Hoseflex, you’re guaranteed quality customer service, and we provide exceptional technical support if any problems arise.

We’ve been providing rubber hoses to the food and beverage manufacturing industry for more than 20 years and have extensive experience. Our products are always manufactured to strict quality control standards and we have a reputation for customising solutions to meet our client’s needs.

We offer a range of food-grade rubber hoses made from quality materials such as NBR, NR, Butyl Rubber Compound, PVC and FEP. Our quality hoses are reliable, durable and resilient to ensure the safety and quality of your food and beverage products.

Choosing the right sanitary hose for food processing ensures your product isn’t contaminated. To learn more about our range of hygienic food-grade rubber hoses, contact our expert team today or online for more information.