Showing all 10 results

Food grade hoses play a pivotal role in ensuring safety and compliance within the food processing and beverage industries. These hoses are specifically designed to meet stringent health and safety regulations, preventing contamination of food and beverages during production, processing, and packaging. The use of a high-quality, flexible food grade hose is essential for transferring various food products, including liquids, semi-liquids, and solids, without compromising the product’s quality or safety. By adhering to international standards, these hoses help manufacturers maintain the highest levels of hygiene and food safety.

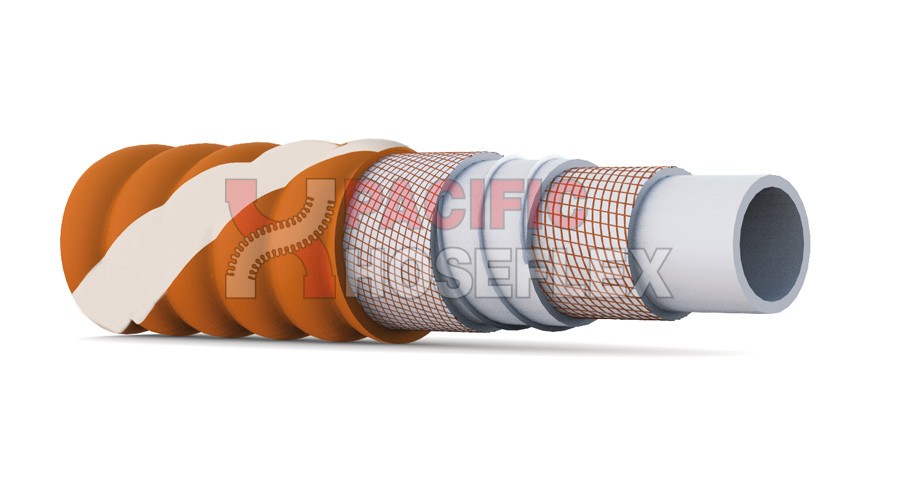

The construction of flexible food grade hoses focuses on durability, flexibility, and resistance to wear and tear, making them ideal for handling a wide range of food products under different conditions. These hoses are made from materials that resist abrasion, prevent bacterial growth, and withstand the harsh cleaning chemicals and high temperatures often used in food and beverage processing. The flexibility of these hoses allows for easy installation and maneuverability in tight spaces, enhancing the efficiency of production lines and reducing downtime caused by hose malfunctions.

Investing in quality food grade hoses brings long-term benefits and cost-effectiveness to businesses in the food and beverage sector. While the initial cost may be higher compared to standard hoses, the durability, reliability, and compliance with health standards of flexible food grade hoses translate to fewer replacements, reduced risk of contamination, and less downtime. Ultimately, choosing the right food grade hose ensures the safety of the food products, protects consumer health, and upholds the brand’s reputation, making it a wise and necessary investment for any food processing or beverage company.

High-quality food grade hoses are specifically designed to meet stringent health and safety regulations, preventing contamination of food and beverages during production, processing, and packaging. They help maintain the highest levels of hygiene and food safety by adhering to international standards.

Flexible food and beverage hoses are built to be durable, flexible, and resistant to wear and tear. They are made from materials that resist abrasion, prevent bacterial growth, and withstand harsh cleaning chemicals and high temperatures commonly used in food processing. Their flexibility allows for easy installation and flexibility in tight spaces, enhancing production line efficiency.

Flexible food grade hoses are used for transferring various food products, including liquids, semi-liquids, and solids, without compromising product quality or safety. They are commonly employed in food processing, beverage production, dairy processing, pharmaceuticals, and cosmetics industries.

Flexible food grade hoses are designed to prevent bacterial growth, resist contamination, and withstand rigorous cleaning and sanitisation procedures. Their smooth surfaces and hygienic materials ensure that food products remain free from contaminants during transfer, helping your company meet strict hygiene and food safety regulations.

Food grade hoses are constructed from high-quality materials that resist bacterial growth and are easy to clean, ensuring optimal hygiene throughout the production process. Their smooth surfaces and non-porous materials prevent bacterial harbourage, reducing the risk of microbial contamination and ensuring compliance with food safety regulations.

Flexible food grade hoses offer versatility and adaptability to accommodate various food processing requirements, such as different temperatures, pressures, and product viscosities. Their flexibility allows for easy routing around equipment and tight spaces, enabling efficient operation and minimising the risk of kinks or blockages in the hose line.