In modern offshore transfer operations hose reels have become increasingly popular for deploying, recovering and storing hoses. While there are many benefits, it’s equally important to address the potential stress factors on hoses and Marine Breakaway Couplings during the winding process.

Pacific Hoseflex is the Australian and New Zealand distributor for KLAW products. We provide:

- Marine Breakaway Couplings.

- Industrial Breakaway Couplings.

- Dry Break Couplers.

- Full Bore Marine Breakaway Couplings.

- Emergency Release Systems.

- Cryogenic Emergency Release Systems.

- Camlocks.

- Swivel Joints.

In a detailed white paper, the experts at KLAW delved into the topic of reducing fatigue on offshore reel transfer systems, providing a comprehensive and detailed explanation. Here’s an overview of some of their findings and recommendations.

About hose reels and Marine Breakaway Couplings

When it comes to managing hoses in transfer applications, hose reels are an extremely practical solution. They offer numerous benefits, such as enhanced storage capacity, improved safety, and more efficient hose deployment and recovery.

By utilising hose reels, operators can effectively organise and protect their hoses, reducing the risk of damage, tangling, and fatigue. Whether in offshore or onshore operations, the use of hose reels simplifies the handling and maintenance of hoses, providing a streamlined and reliable solution for fluid transfer needs.

Marine Breakaway Couplings also play a key role in preventing spills, protecting assets and minimising the risk of injuries. They play a critical function by shutting off the flow in both the upstream and downstream directions and they separate when triggering events occur. This includes excessive stress on the hose caused by vessel drift beyond set parameters and pressure surges.

When using both hose reels and Marine Breakaway Couplings several things can impact the stress levels of the hoses and couplings.

Hose reel applications – factors to consider

The main concern when using both these components comes from the interruption in the natural radius of the coil caused by the coupling’s presence. This is called coil discrepancy and can lead to stress on both the hoses and the breakstuds of the Marine Breakaway Coupling.

The results of coil discrepancy

Coil Discrepancy determines the contact angle between the hose and the inner wound hose. Without a Marine Breakaway Coupling, the contact angle remains unaffected, but when a coupling is present, the contact angle becomes imperfect due to coil discrepancy. The length of the Marine Breakaway Coupling and the radius of the hose reel influence the extent of coil discrepancy and subsequently impact stress levels.

The length of a Marine Breakaway Coupling directly correlates with the level of stress points it induces. However, it can be mitigated by the radius of the hose reel. A larger reel radius helps to minimise coil discrepancy, thereby reducing stress on the coupling.

Alternatively, opting for a shorter Marine Breakaway Coupling can also contribute to a reduction in coil discrepancy, leading to decreased stress levels. By carefully considering the coupling length and reel radius, operators can effectively manage stress and enhance the overall durability of the system.

Stress factors

When we’re looking at hose reels and Marine Breakaway Couplings, two stress factors come into play; weight impact stress and hose kink stress.

Weigh impact stress: This type of stress is caused by the physical weight of the Marine Breakaway Coupling and the displaced weight of the hose due to the imperfect contact angle. It directly impacts the breakstuds.

The KLAW Marine Breakaway Coupling is designed to resist bending moments and primarily respond to axial forces, reducing the chances of unintended activation. However, frequent stress on the breakstuds from hose reel operations may require additional maintenance attention to prevent fatigue.

Hose kink stress: When there is a space between the Marine Breakaway Coupling section and the inner hose, hose kink stress can occur, resulting in hose fatigue.

The KLAW Marine2 Breakaway Coupling – Pacific Hoseflex

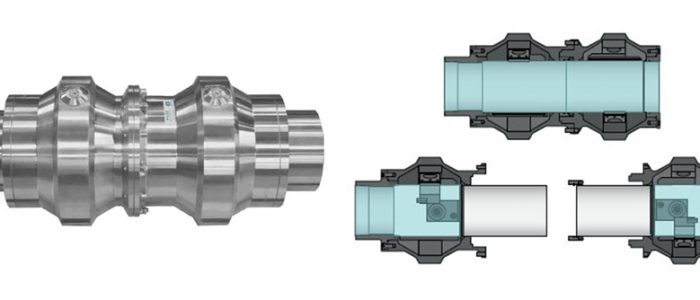

Pacific Hoseflex offers the KLAW Marine2 Breakaway Coupling to address stress issues related to hose reels. The previous KLAW Marine Mark 1 Breakaway Coupling for offshore applications was the lightest and shortest on the market, with a flip-flap valve with alternative valve designs such as the poppet valve.

The KLAW Marine2 Breakaway Coupling is 15% lighter and 10% shorter than this original coupling, which exponentially reduces stress to hose reel applications and decreases fatigue on inner hose and outer hose sections as well as the Marine Breakaway Coupling breakstuds.

An easy reset facility is now fitted as standard to all KLAW Breakaway Couplings, allowing operators to service and reset the coupling without the need to detach the 4 couplings from the line. This reduces fatigue on the hose which is caused by the additional handling and interference when detaching and reattaching the coupling.

The KLAW Marine2 Breakaway Coupling provides an innovative solution to maintain the integrity and efficiency of offshore operations. By addressing coil discrepancy, weight impact stress and hose kink stress you can minimise the risk of asset damage, downtime and injuries.

For more information about the KLAW Marine2 Breakaway Coupling, contact our product experts.